Microtunneling

Minimal Surface Disruption, Maximum Underground Efficiency

Microtunneling Capabilities

Microtunneling is a specialized form of trenchless construction that utilizes advanced, specialized equipment, including a microtunnel boring machine (MTBM), to construct tunnels for utility installations. This advanced technique is ideal for urban environments where traditional open-cut methods would cause significant traffic congestion and business interruption. Our comprehensive microtunneling service delivers remote-controlled boring systems that maintain exceptional accuracy while installing pipes ranging from 12 to 120 inches in diameter.

Pate Garver’s fleet of microtunneling equipment enables us to perform installations with tunnel drives ranging from 8 inches to 96 inches in nominal diameter.

ALL ABOUT

Microtunneling FAQ’s

Microtunneling is a highly precise, remotely-controlled tunneling method that revolutionizes underground utility installation in urban environments. This advanced trenchless technology allows us to install pipes and utilities accurately while minimizing surface disruption – a crucial advantage in busy urban areas where traditional open-cut methods would severely impact daily activities.

Our specialized microtunneling equipment can bore through varied geology while maintaining exact grade and alignment. This means getting pipes exactly where they need to be, even under buildings, roadways, or waterways. For projects where interruptions aren’t an option or where depths make traditional methods impractical, our microtunneling service offers the practical solution you’re looking for.

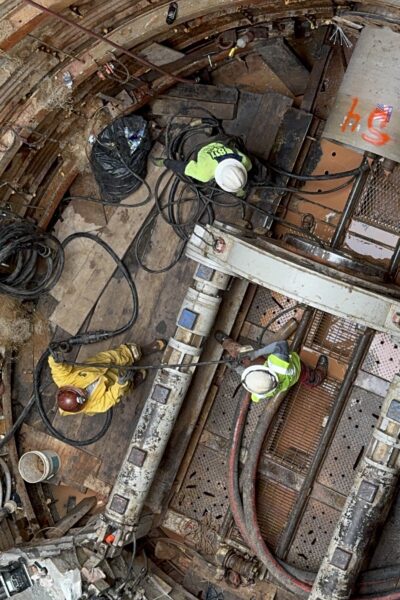

Unlike conventional tunneling methods, microtunneling employs a sophisticated tunnel boring machine (TBM) operated from an above-ground control station. The process begins with the installation of entry and exit shafts at either end of the planned tunnel route. Our skilled operators then guide the TBM remotely using a laser guidance system, ensuring accuracy to within millimeters of the designed path. vThe microtunneling system simultaneously excavates soil and installs pipe segments, maintaining constant support of the tunnel face to prevent ground settlement. This approach is particularly valuable in areas with high groundwater tables or unstable soil conditions, where other methods might pose significant risks.

Exceptional Precision: Laser guidance systems ensure accuracy within millimeters

Minimal Surface Impact: Only requires entry and exit points, preserving surface infrastructure

Ground Stability: Continuous pressure balance prevents settlement and protects nearby structures

Versatility: Effective across various soil conditions, including below the water table

Environmental Protection: Significantly reduces the carbon footprint compared to open-cut methods

Cost-Effective: While initial costs may be higher, the reduced need for surface restoration and shorter project timelines often result in overall cost savings

Below the Chaos: Where Infrastructure Meets Ingenuity

We don’t just dig; we precisely bore pathways for infrastructure that keep everything above ground working. Our specialized microtunneling equipment can drive through varied geology while maintaining exact grade and alignment. This means getting pipes exactly where they need to be, even under buildings, roadways, or waterways. Because when your project can’t afford the disruption of cut-and-cover methods, our microtunneling service offers the practical solution you’re looking for.